History

Gudbrandsdalens Uldvarefabrik AS was established in Lillehammer in 1887 and is today one of the world's leading suppliers of furniture and upholstery fabrics. Annually, the factory produces approximately 600,000 meters of textile.

The mill specializes in woolen fabrics and has a unique production line where all processes take place under the same roof, from raw material to finished product. This means that we have control over the entire value chain, and with design, development and production close to each other, we have high flexibility and can create high quality products.

We produce textiles with nature as a source and input factor and with minimal use of chemicals. Wool is a natural raw material with natural technical properties that is renewable and biodegradable. The factory is known for long-lasting products and has received the DOGA mark (formerly the Mark for Good Design) 20 times for 23 products. One of our most famous textiles is the classic Hallingdal 65, designed by Nanna Ditzel.

History

-

1887 - Gudbrandsdalens Uldvarefabrik AS was established in Lillehammer by Bernt Otto Johnsen, then under the name Gudbrandsdalens Uldspinderi. Back then it was a modest spinning mill.

-

1889 - The company expanded production and changed its name to Gudbrandsdalens Uldvarefabrik.

-

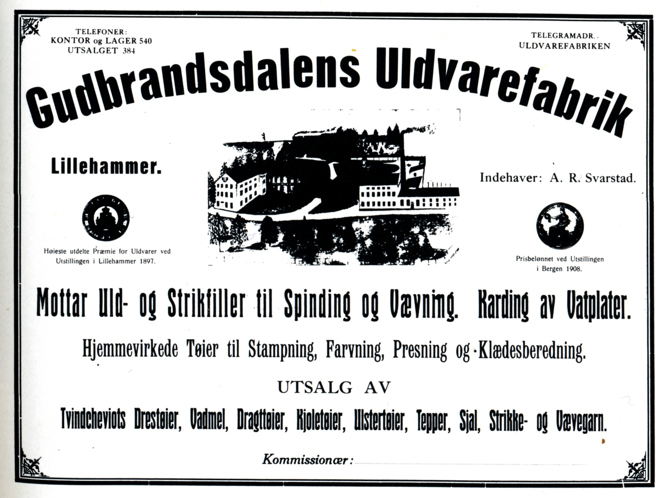

1912 - Andreas R. Svarstad bought the company. He came from Indviken Uldvarefabrik where he had sold his share and invested this in GU.

-

1914 - Conversion from hydropower to electricity. The list of new buildings, extensions and investments in Andreas R. Svarstad's time is impressive. The results were growth in production, number of employees and turnover.

-

1920 - In the 1920s, dress clothes and suit fabrics became important parts of production, and coat fabrics became a major article in the 1930s. The sale in the city had, among other things, fabrics for suits, dresses, suits, carpets, shawls, knitting and weaving yarn. Large investments in buildings and machinery.

-

1925 - The first upholstery fabrics were developed for Th. Lunde AS (Lundemøbler)

-

1925 - The basis for the "bunad" established by Hulda Garborg. Fabric from the factory was used where it naturally suited.

-

1926 - First delivery of upholstery for train to NSB - Wagon AB0118.

-

1930 - In the 1930s, clothing fabrics were still big. Large investments were still made in buildings and machinery.

-

1938 - Andreas Rasmus Svarstad hands over the company to his sons Ragnvald and Asbjørn.

-

1940-45 - During the war years, production continued, but characterized by a lack of raw materials and electricity rations. "Something was going on all the time".

-

1947 - New dyehouse building

-

1949 - New process building

-

1950 - In the 1950s, production was first aimed at the ready-to-wear industry, then especially women's ready-to-wear. Eventually, production became more specialized in upholstery fabrics. Quality, design and reliable deliveries became the company's hallmark.

-

1950 - Purchase of rights to, among other things, the "Spælsau" quality (129), from Voss Ullvarefabrikk. A larger clothing market opened up.

-

1960 - Employment of the first chief designer - Hans Hosak.

-

1964 - In 1964, Gudbrandsdalens Uldvarefabrik AS switched to buying wool from New Zealand, as this was cleaner and had a more consistent quality. In terms of price, there was no difference, as prices on as the price of wool followed international auctions. In the same year, the commission system to handle the direct submission of wool from local farmers ceased.

-

1965 - Hallingdal was launched for the first time. In addition, Gudbrandsdalens Uldvarefabrik AS had its first delivery to cruise ship M/S Sagafjord. A new generation of weaving machines - Sulzer Projectile machines - was also introduced in the new weaving mill building. These had significantly higher quality and efficiency.

-

1966 - In 1966, it was decided that the production of clothing fabrics, with the exception of base fabrics and blankets, should be closed down. Production of plaid fell away shortly afterwards.

-

1976 - Arne Svarstad, who managed the company from 1963-1984, transferred his shares to his son, Ragnvald.

-

1980 - Establishment of the Familien Svarstads Stiftelse to promote educational purposes within the factory's industry.

-

1987 - Gudbrandsdalens Uldvarefabrik celebrated its 100th anniversary and got a new plush building.

-

1992 - Andreas Svarstad, who managed the company from 1984-1994, transferred his shares to his son, Frode Svarstad.

-

1994 - Ragnvald Svarstad took over from Andreas in 1994 and managed the company until the year 2000. The Olympics in Lillehammer increased the need for clothing fabrics dramatically. Over 100,000 m were delivered in one year. Large investments were made in machinery.

-

2002 - In order to increase the focus on marketing and sales of fabric for national costumes, the segment was established as a separate department.

-

2011 - The company structure was changed. GU was converted into a holding company and a property company and an operating company were established.

-

2013 - Extensive modernization was carried out through major machine investments in dyeing, spinning and weaving.

-

2014 - Phasing in Norwegian wool in the basic fabrics is appropriate. Through this, the Norwegian bunade became even more Norwegian and it took back its origins.

-

2015 - Acquisition of Mandal Veveri and a major expansion of the bunad collection. With this, GU became by far the largest producer of fabrics for national costumes..

-

2016 - Innfasing av norsk ull i møbelstoffene der det var mulig. Det ble utviklet en egen kolleksjon i 100% norsk ull sammen med Flokk. Denne mottok "Merket for god design" i 2015.

-

Today - Today, GU is one of Europe's leading suppliers of furniture and upholstery fabrics. For more than a hundred years, the factory has developed wool's many possibilities. Solid knowledge of the wool's journey from nature to natural products is the reason why our wool fabrics are known for their very high quality. We develop and produce upholstery fabrics, the transport sector (cruise ships, ferries, buses and trains) and for the clothing market. Virtually every other bunad in Norway has textiles from us.

Priser og utmerkelser

-

2023 - Alfa Sko - Produktprisen (Norsk Industri) for sko i ullstoff fra GU

-

2023 - Hallingdal 65 - Klassikerprisen (Norsk Industri)

-

2023 - DnB - Årets Ringvirkingerbedrift

-

2022 - Alfa Sko - Norwegian Outdoor Award for sko i ullstoff fra GU

-

2017 - Sirdal, Setesdal, Suldal - 100% norsk ull - Merket for God Design (DOGA)

-

2015 - Årets Produsent - Bo Bedre

-

2015 - Prinsdal - Merket for God Design

-

2007 - Scalo - Merket for God Design

-

2003 - Odal - Merket for God Design og Hedersmerket

-

2002 - Edel Sengeoverkast - Merket for God Design

-

2000 - Mundal - Merket for God Design

-

1999 - Møbelstoff til Gardermobanen / Flytoget - Merket for God Design

-

1998 - Møbelstoff til Rena Leir - Merket for God Design

-

1998 - Mandal - Merket for God Design

-

1996 - Dypdal - Merket for God Design

-

1996 - Rypdal - Merket for God Design

-

1996 - Fiksdal - Merket for God Design

-

1992 - Svandal - Merket for God Design

-

1991 - Eidsdal - Merket for God Design

-

1991 - Toppdal - Merket for God Design

-

1971 - Holmedal, Heggedal og Hunndal - Norsk Designcentrums Pris

-

1967 - Rosendal - Merket for God Design

-

1965 - Stordal - Merket for God Design

-

1988 - Landsforbundets Norsk Forms Ærespris

-

1930 - Diplom for Sølvmedalje for møbelstoffer med norske mønstre på Trøndelagsutstillingen

-

1928 - Diplom for Sølvmedalje for gode ulltepper og plaids, portiérstof og møbelstof på Landsutstillingen i Bergen

-

1927 - Diplom for Guldmedalje for vevede tøier, portiérer, tepper o.l. på by

-

1898 - Tilkjendt Gudbrandsdalens Uldspinderi for spundet garn på Landsutstillingen i Bergen.

-

1897 - Diplom for Sølvmedalje tilkjendt Gudbrandsdalens Uldspinderi for garn på Landbrugs- og Industri-Udstillingen i Lillehammer

The oldest craft in our history

Processing wool is perhaps the oldest craft in the history of the human race. It was a technological breakthrough when man learned to card and spin yarn from sheep's fur, and weave it into clothes that protected against the cold. It probably happened sometime in the Neolithic, about 8,000 years ago. The first implements were simple and ingenious. The yarn was spun by hand with tin. In 1530 the stingray was invented. In Norway, the art of spinning and weaving became known in the Bronze Age.

The sheep is the main character in textile history. It is one of the first animal species to be domesticated by man. It gave them food and clothes. There are today just over 1 million sheep in Norway. No other fiber - natural or artificial - has outperformed wool. Linen has a small area of use and silk is expensive. Cotton has many uses, but it does not replace wool, nor today's man-made fibres. Wool combines so many good properties that it simply cannot be replaced. Wool is not only warming, but it is also political, technological, economic and cultural history.

Processing wool is perhaps the oldest craft in the history of the human race.

The textile industry is growing and Gudbrandsdalens Uldvarefabrik is established

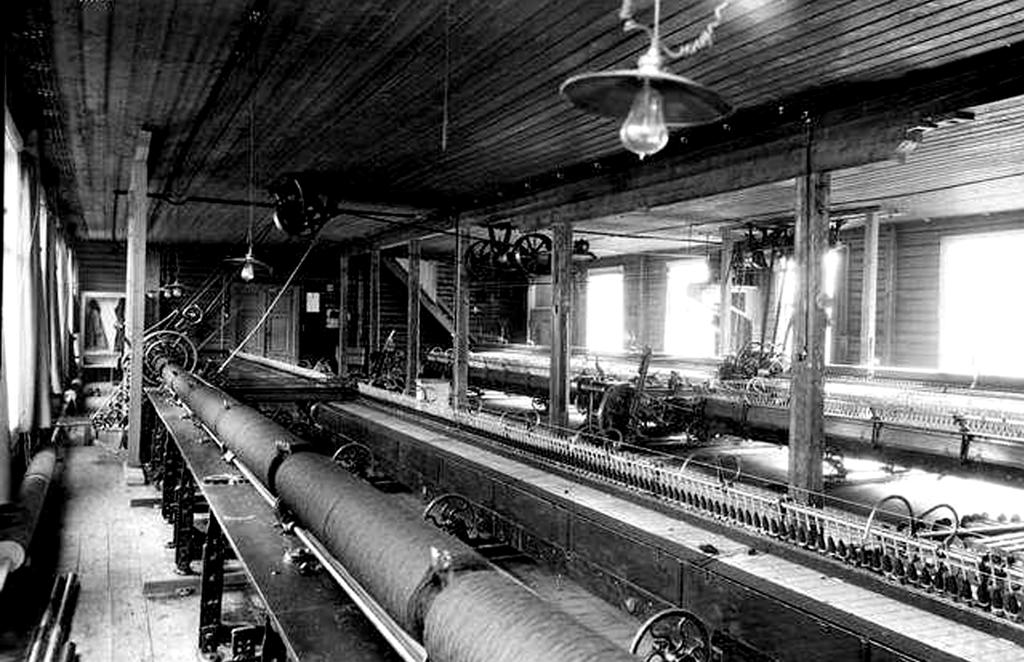

Our modern machine and industrial society was born in England, and the textile industry was the spearhead of the new era. The industry eventually also grew in Norway in the mid-1850s. In 1887, "Gudbrandsdalens Ulspinderi" was established in Lillehammer with a workforce of 8 people. The first machine park consisted of two spinning chairs, two carding units and a mixing machine.

In the first years, production was rental spinning of wool from the sheep farmers in the area. The supply of raw materials was good, and not long after there was a need to expand, and a new two-storey building was erected. In addition, four double-width and two single-width looms were purchased. The new building also made room for colors in the furnishings. 25 more people were employed. Now the company had become a "complete" woolen goods factory. In 1889 it changed its name to "Gudbrandsdalens Uldvarefabrik".

In addition to yarn production, the factory took up the production of sjeviou (thin wool quality) and verken (two shafts), half-wool dress shirts, wadding and gray wool carpets. The company won recognition for quality products. The textile factories were generally the first real workplaces for women in Norwegian industry, and the difference between women's and men's wages was not that great.

New ownership and new thoughts

In 1912, the factory got a new owner. It was an experienced business man who took over the company. Andreas Rasmussen Svarstad was born in Ålesund. He worked at Bergen Klædefabrik and Sogndal Uldvarefabrik, and together with his brother-in-law Wald P.Skaaden he started Indviken Uldvarefabrik (Innvik) in Nordfjord.

Andreas eventually sold his share to his brother-in-law and traveled to Lillehammer, where he bought Gudbrandsdalens Uldvarefabrik. He saw the opportunity in the area with significant sheep farming and good communication by rail.

Svarstad is considered the factory's "second founder". The factory needed a renewal, and he combined sobriety with foresight and determination. He also had the ability to get along with employees on the floor and in the office. He had a background that enabled him to carry out both the business and the technical assessments himself, and was thus able to provide the company with effective unit management.

During the war there was great demand, and the fact that Norwegian wool was the most important raw material benefited the factory.

World War I and high demand

There was a steady rise in the years before the First World War. During the war there was great demand, and it benefited the factory that Norwegian wool was the most important raw material, since the supply of raw materials fell drastically. The factory had also recently switched to electric power.

The autumn of 1920 was marked by the post-war depression. The industry had declining turnover, and many went bankrupt. But in Lillehammer there was a big exception: at Gudbrandsdalens Uldvarefabrik, operations went on without labor disputes and investments continued on an ongoing basis. Year by year, the machine park grew. Eventually, dress clothes, suit and coat fabrics became important parts of the production. In 1925, the factory took up the production of furniture fabric. Gradually, the factory faced sharp competition from foreign factories that produced cheaper.

"The cheapest items sell the easiest. But it certainly pays to buy quality goods. In terms of quality, Norwegian textile goods stand above the foreign ones." A.R Svarstad.

World War II and continued operations

In 1937, the brothers Asbjørn and Ragnvald Svarstad took over the factory. They took over at a worrying time. The threats of war in Europe loomed large. Less than a year later, World War II broke out. There was a lot of uncertainty and new unforeseen problems. The first half of the 1940s was a struggle, but due to the planned investment work in advance, the factory was still able to use the time for maintenance and partial renewal. The shortage of goods also benefited the factory.

The factory managed to maintain operations throughout the war years, but not all production all the time. A shortage of raw materials could stop parts of it. Power rationing could also interrupt operations.

The textile factories were allocated quotas of raw materials, but these were small, and there were strict restrictions on their use. It was not permitted to process goods made of pure wool. A common mix was 60% sjoddi, 20% wool and 20% cotton. Most of the wool the factory received during the war was Norwegian, but lots also came from Germany.

Scarcity and difficult years

The supply situation for people's daily needs began to become difficult. The food shortage became palpable. The company used its connections to obtain supplies that could benefit the employees. Many still remember the Uldvarefabriken's potato field where employees got their plots. Some were assigned a forest area where they could chop wood. For many, the handshake from the company helped them get through the war years.

When the war was over in Norway, the first post-war decade was difficult. The country was to be rebuilt. All attention was focused on getting production back to normal. The lack of spare parts had made maintenance difficult during the war years. The warehouses were empty and the supply of raw materials and fuels insufficient. In return, sales went very well. Customers came to Lillehammer from all over the country to secure goods. The need for the renewal of textiles of all kinds appeared, from clothing to furniture fabric.

International competition in the clothing industry

It was not until the end of the 1950s that the situation normalised. The competition gradually became tougher throughout the textile industry. Both from abroad and between the Norwegian factories. The management at the factory presented an aggressive attitude to assert itself in the competition. More and more of the collection was oriented towards the clothing industry. Most important were women's coats and suits. Quality, good design and reliable delivery were characteristics the company was known for.

The factory competed in a labour-intensive and risky market. Gradually, the Norwegian clothing industry began to fail, and many had to give up when import restrictions were removed and customs limits were lowered.

The new artificial fibers

Norwegian wool dominated in the first post-war years, but it was not long before foreign wool and artificial fibers came into full force. The very first nylon product we met were the English parachutes. The silk stockings disappeared and were replaced by nylon stockings.

Some thought the chemists had now made the natural fibers redundant. It turned out to be wrong. The natural fibers have properties that the artificial fibers cannot imitate. In addition, synthetic fibers have their weaknesses in that they are flammable and develop static electricity. Today, the situation is such that the world no longer has enough natural fibers and needs the artificial fibers as a supplement. Mixtures are often used.

Norwegian wool is losing ground

Norwegian wool has properties that make it often preferred for hand knitting yarn, knitwear and carpets. Sheep that graze in forests and fields often get vegetables in their fur that are difficult to remove. Wool from New Zealand, on the other hand, came from pigs that roamed open grasslands, which gave a cleaner and smoother quality. In addition, wool cost almost the same as Norwegian, even though it was transported far, as prices for woolen fabrics followed international auctions. The Norwegian wool was simply not of good enough quality to be used in production. In 1964, Gudbrandsdalens Uldvarefabrik AS switched to buying wool from New Zealand, as this was cleaner and had a more consistent quality.

New specialty: upholstery fabric

Specialization on the product side was the answer to the new situation for an industry facing the world. The high-cost country Norway could not compete on price, therefore quality in production and professionalism in product development and marketing became even more important than before. Gudbrandsdalens Uldvarefabrik stands as a leading representative of the part of the textile industry that managed the changeover and benefited from it. The choice of specialization fell on a production the factory had extensive experience with: furniture fabric. In 1966, specialization had progressed to such an extent that a decision was made to cease production of upholstery fabrics.

This decision became the guiding principle for further investment programs in the factory. There was an ongoing replacement and acquisition of newer and more advanced machines. Many looms were acquired, the cadrery got a new one

The design department is being strengthened

In 1960, the first chief designer was employed at the factory. Hans Hosak came to Norway from a Danish textile factory. Together with his colleague Kari Skogstad, he left his mark on Uldvarefabriken's collections. He had both a technical background and an eye for the market. Hosak introduced "multicolour" in the furniture fabrics, i.e. multi-coloured fabric woven from yarn with four or five color components in each thread. He launched the textile Stordal in several colours, which was a hit, and of which millions of meters have since been woven.

In 1966, the board made the decision in principle to close down the production of clothing fabrics, apart from underwear fabrics. A new chapter was to be written with specialization in furniture fabrics in a technologically advanced production apparatus. The production of furniture fabrics had roots back to the 1920s, and they had a high level of expertise.

Hallingdal-65

The furniture fabrics from Uldvarefabriken all have names that end in -dal. Each valley has its own design with different color combinations. In the 1960s, the contact with the textile man Percy von Halling-Koch and his Halling Koch Design Center became particularly valuable. He was initially interested in factories that could produce his textiles on a license basis. This was then sold through the large wholesale company Kvadrat in Ebeltoft. A visit he made to Lillehammer was the prelude to this collaboration.

The first von Halling-Koch design by the famous textile artist Nanna Ditzel was a success. Like Uldvarefabriken's other fabrics, it obviously had to be named after -dal. In honor of the new customer, it was Hallingdal.

Hallingdal, which came on the market in 1965, is still our bestseller. Gudbrandsdalens Uldvarefabrik has sold an incredible 8,622,876 meters or 8,263 km. From Lillehammer to Beijing it is 6,958 km. The amount of wool that has gone into this volume corresponds to 1,610,000 sheep. Today, GU has the sales rights in Norway, while Kvadrat sells to the rest of the export market. All of Hallingdal is still produced in Lillehammer.

The choices in the future

In 1966, it was decided that production of the clothing fabrics, with the exception of national costume fabrics and blankets, was to be discontinued. The focus was on fupholstery fabrics. In 1976, Arne Svarstad, who managed the company from 1963-1984, transferred his shares to his son, Ragnvald. The company then had around 100 employees and five main departments; the spinning mill, the bobbin mill, the weaving mill, the nupper mill and the dye mill / finishing. There were fewer and fewer players in the industry and the environment became small when it came to textiles. It was important to seek professional inspiration and travel to where it happened.

In 1987, Gudbrandsdalens Uldvarefabrik celebrated its 100th anniversary and gained a new profile. There were wishes and demands from the market to follow the fashion wave with cheap fabrics and a more reasonable price. The factory refused to participate in this gallop. A stamp of quality had been built up that they did not want to jeopardize. There was also a change in the furniture market in that retailers offered customers to choose their own fabric for the furniture. In this way, the customer had the opportunity to choose quality fabrics.

National costume textiles in focus and acquisition of Mandal Veveri

In 1992, Andreas Svarstad, who managed the company from 1984-1994, transferred his shares to his son, Frode Svarstad. In 1994, Ragnvald Svarstad took over from Andreas and managed the company until the year 2000. "The Svarstad Family Foundation for the Promotion of Educational Purposes" was established in 1980. The Olympics in Lillehammer in 1994 increased the need for clothing fabrics dramatically. Over 100,000 m were delivered in one year. Large investments were made in machinery. From 2002, it was decided to focus on the marketing and sale of underwear fabrics, and the segment was established as a separate department.

In 2011, the company structure was changed and GU was converted into a holding company and a property company and an operating company were established. In 2013, extensive modernization was carried out through major machine investments in dyeing, spinning and weaving. In 2015, Gudbrandsdalens Uldvarefabrik bought Mandal Veveri. There was a major expansion of the bunad collection, and GU became by far the largest producer of bunad fabrics.

From 2014-2016, Norwegian wool was brought back into production.

New phasing in of Norwegian wool

From 2014-2016, Norwegian wool was brought back into production. A separate collection in 100% Norwegian wool was developed together with Flokk and Sandnes Garn. This received the "Mark for good design" in 2015. Much of the work went into making the Norwegian wool clean enough to be used in furniture textiles.

Norwegian wool was incorporated into all furniture and upholstery fabrics where possible. Through this, the Norwegian bunade became even more Norwegian and took it back to its origins.

World-class textiles

Today, GU is one of Europe's leading suppliers of furniture and upholstery fabrics. For more than a hundred years, the factory has developed wool's many possibilities. We design, develop and produce fabrics for the furniture industry (contract and home furniture), the transport sector (cruise ships, ferries, buses and trains) and for the clothing market. Virtually every other bunad in Norway has textiles from us. The factory has produced and delivered goods to well-known brands such as Louis Vuitton, Frozen - The musical, Renault, Royal Caribbean Line, Hurtigruta, Ulvang and the shoe manufacturer Alfa.